New Breakthrough In Prefabricated Floor Slab Molds

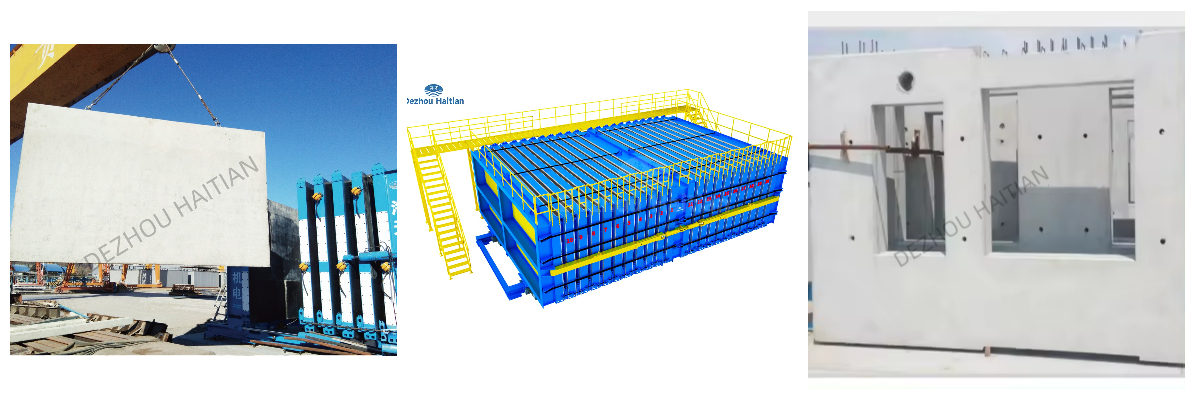

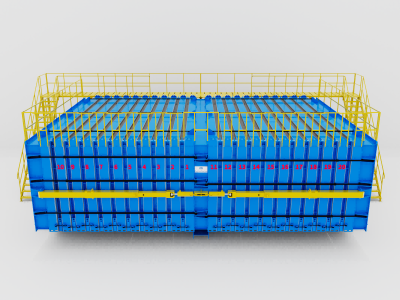

Currently, the process of building industrialization is continuously accelerating, and the concrete wall panel mold technology, as the core production tool, is also undergoing a crucial upgrade. Recently, a leading industry enterprise announced a new breakthrough in the mold system field. This progress not only significantly improves the production quality and efficiency of prefabricated components, but also injects innovative impetus into the entire prefabricated building industry chain.

Technical Breakthrough: Integration of Intelligence and Lean Manufacturing

The core of this technological breakthrough lies in the deep integration of intelligent control systems into the molds. Traditional production relied heavily on manual operations and experience-based judgments. However, the new generation of molds, equipped with built-in sensing components, can monitor the concrete pouring status, density, and temperature changes in real time, achieving precise control of the production process. At the same time, the standardized and modular design of the molds has reached a new level. Through rapid mold replacement technology, a single production line can flexibly adapt to the production of various sizes of floor slabs, significantly enhancing the flexibility of production scheduling and meeting the growing market demands for customization and diversity.

Efficiency Enhancement: Promoting Upgrading of the Entire Supply Chain

The direct impact of this breakthrough is a significant leap in the quality of prefabricated components. Intelligent control ensures that the strength, flatness, and dimensional accuracy of each prefabricated floor slab remain at an extremely high level, laying a solid foundation for efficient and high-precision on-site installation. For the construction team, this means faster construction speed, less reliance on manpower, and more controllable overall costs. This technology has been successfully applied in actual large-scale residential and commercial complex projects, receiving positive feedback from developers and construction companies. The industry generally believes that this innovation in concrete wall panel molds will strongly promote the liberation of architectural design concepts, providing the possibility of industrialized production for more complex and more beautiful architectural forms.

Future Outlook: Green Sustainability Becomes the Development Direction

Looking ahead, the breakthrough direction of this technology will further integrate with the concept of green buildings. The research and development focus has begun to tilt towards extending the service life of molds, reducing production energy consumption, and optimizing material utilization. Through technological iterations, the reduction of resource consumption and waste generation in the production process enables prefabricated buildings to not only be constructed quickly but also demonstrate environmental advantages throughout their entire life cycle. This advancement in concrete wall panel molds marks that China's building equipment manufacturing industry is shifting from following to leading, and will provide important technical models and practical experiences for global building industrialization.