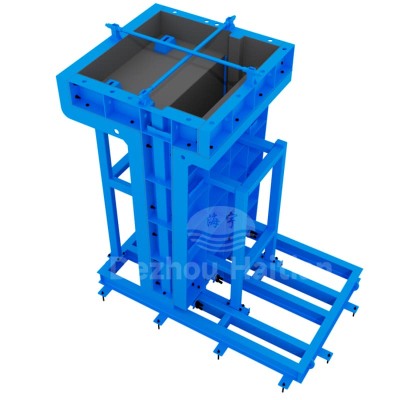

Precast Concrete Box Culvert Mold

1. Customizable cross-sections and internal cavities to match engineering drawings, load requirements, and project-specific layouts.

2. Robust steel structure with reinforced framing ensures long-term dimensional stability during repeated casting cycles.

3. Smooth, precision-machined form surfaces improve concrete finish quality and shorten post-processing work.

4. Efficient opening and closing mechanism simplifies demolding, accelerates turnaround time, and reduces labor intensity.

5. Compatible with optional vibration or sealing systems to enhance compaction and prevent slurry leakage.

6. Modular side panels and adjustable components support diverse culvert sizes while reducing transport and installation complexity.

7. Designed for heavy-duty precast production, offering reliable performance with straightforward daily maintenance.

The Precast Concrete Box Culvert Mold is built to make everyday production feel straightforward and dependable. It focuses on delivering culvert sections that come out with steady geometry and tidy surfaces so that teams spend less time correcting edges and more time preparing shipments. Thoughtful details in frame design and contact surface finishing help concrete release cleanly, which means less fiddly rework and a smoother cadence on the shop floor. The system is made to fit into existing workflows, allowing lifting and transport operations to remain predictable and minimizing the disruption that new tooling sometimes brings. Customization is treated as part of normal delivery, so drawing-specific adjustments for cavity layout, lifting points, and embedded features are handled with practical readiness rather than as afterthoughts. Optional compaction and curing enhancements are available to suit different mixes and climates, helping producers match local materials and seasonal variations. Overall, this mold aims to be a practical teammate in production: quiet, reliable, and ready to help a crew meet deadlines with consistent quality.

1.Structural Design that supports reliable alignment and operator ease

The mold shows its intent through a solid welded frame and well considered mating faces that keep alignment honest over many cycles. Panels open and close with a gentle authority that avoids sudden jolts and lets operators work with better rhythm. Access pathways are arranged so reinforcement placement and embedded parts are not awkward tasks; this naturally reduces handling missteps and lowers the chance of mistakes during setup. Surfaces that meet concrete are treated to encourage smooth release, helping cast pieces emerge with cleaner edges and less need for surface touch up. In practice, this design reduces the physical strain on teams and turns what can be a tricky operation into a routine task that the crew can rely on day in and day out.

2.Application fit that mirrors infrastructure realities

This mold answers the needs of municipal and infrastructure projects by accommodating a range of culvert profiles and internal cell arrangements. It is suited to drainage channels, stormwater passages, utility corridors, and cable tunnels, providing the sorts of internal geometries that help water flow and service routing work as intended once installed. The ability to adapt cavity layout and embed locations means the same tooling logic can be applied across different job types, which helps contractors avoid the overhead of many single-purpose molds. Because the tooling integrates with common lifting and curing practices, it becomes a practical choice for plants that balance a variety of orders without wanting to overhaul their handling procedures for each new job.

3.Materials and finishing that emphasize longevity and good outcome

The mold’s longevity comes from selecting structural steel and fabrication practices that resist deformation under repeated use. Welds and reinforcements are placed to follow stress paths, protecting geometry where it matters most. Contact plates and internal surfaces receive treatments aimed at reducing adhesion and promoting a tidy surface on demolded concrete. Those finishing choices have a straightforward payoff: fewer stuck edges to hammer free, fewer patched corners, and a better look coming off the line. Protective coatings on exposed metal also help the equipment weather daily washdowns and outdoor stowage without surrendering performance over time, so the mold behaves like a dependable tool rather than a fragile instrument.

4.Production workflow benefits that smooth the path from pour to release

The mold is designed around the steps that teams already follow—prepare, place reinforcement, pour, consolidate, cure, and release—making each of those steps feel predictable. If extra compaction is desired, the system readily accepts vibration options that focus energy where it helps the concrete settle without causing unwanted slurry loss. Demolding unfolds in a controlled, comprehensible sequence so finished pieces can be handled safely and moved into curing or stacking without scramble. That predictability raises the share of acceptable units coming off the line and shortens the gap between casting and shipping readiness, which is a quiet but meaningful improvement to daily operations.

5.Customization and support that make the mold a practical partner

This product treats customization as a practical service rather than a boutique add on. Cavity shapes, wall thickness allowances, embed placements, and lifting point arrangements are adapted to customer drawings so the mold fits into project specifications instead of forcing projects to bend to the tool. On the service side, setup assistance, operator familiarization, and parts provisioning are part of the experience, helping teams move from delivery to steady output without prolonged trial and error. With that support, the mold becomes more than metal and welding; it becomes part of a producer’s everyday toolkit for reliable culvert production.