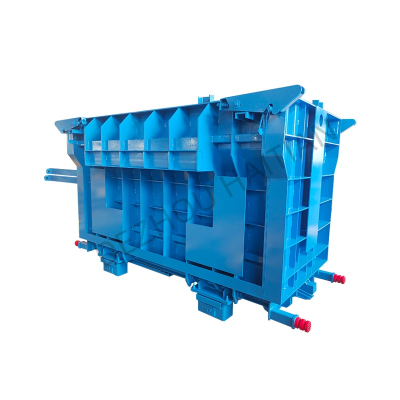

Precast Fence Panel Mold

1. Deepening design can be carried out based on the customer's component drawings.

2. The structure is reasonable, with good sealing performance and no leakage of mortar.

3. Good bearing capacity, excellent durability, convenient operation and construction.

The precast fence panel mold is widely applied in residential, municipal and industrial fields, suitable for scenarios like courtyard fencing, factory boundary isolation and municipal greening enclosures—all relying on this precast fence panel mold for reliable production. It has clear advantages: strong reusability cuts material waste, stable forming ensures uniform fence panel quality, and it streamlines casting to save construction time, making the precast fence panel mold a time-saving solution. In standards, the precast fence panel mold meets industry requirements for material strength and dimensional precision, complying with common regional or international specifications to guarantee safe use. Its key features include modular design for flexible combinations and compatibility with various concrete mixes, which lets the precast fence panel mold adapt to diverse fence structure needs.

Compared with traditional on-site casting molds or other types of fence production tools, the precast fence panel mold has significant advantages that make it stand out in the market. First of all, it has excellent reusability. The precast fence panel mold is usually made of high-strength steel or wear-resistant composite materials. After strict heat treatment and precision processing, it has strong wear resistance and structural stability. A single mold can be reused hundreds of times even under frequent casting operations, and the dimensional accuracy of the produced fence panels will not decrease due to multiple uses. This not only reduces the cost of mold replacement for enterprises but also avoids the material waste caused by the scrapping of disposable molds, which is more in line with the concept of economical and environmental protection. Secondly, it can greatly improve production efficiency. Traditional on-site casting requires on-site setting up molds, pouring, and maintenance, which is greatly affected by weather, site conditions, and other factors,and the production cycle is long.

The precast fence panel mold can be used in the factory for centralized prefabrication. The production process is standardized and streamlined. Multiple molds can be operated at the same time, and the fence panels can be produced in batches. After the prefabricated fence panels are mature, they are directly transported to the construction site for installation, which greatly shortens the on-site construction time and improves the overall project progress. Thirdly, it ensures the stable quality of fence panels. The precast fence panel mold has a precise structural design, with seamless splicing between the mold cavities and accurate positioning of the internal components. During the pouring process, the concrete can be evenly filled in each part of the mold cavity, avoiding problems such as bubbles, hollowing, and uneven thickness of the fence panels caused by improper mold design. At the same time, the standardized production environment in the factory is easier to control the temperature, humidity, and curing time of the concrete, ensuring that each fence panel has consistent strength, density, and appearance quality. Finally, it has strong adaptability. It can be customized according to the specific needs of customers, such as adjusting the size, shape, and surface pattern of the mold cavity to produce fence panels of different specifications and styles. Whether it is a simple straight fence panel or a fence panel with complex patterns and special shapes, the precast fence panel mold can meet the requirements, providing more possibilities for the personalized design of fence projects.