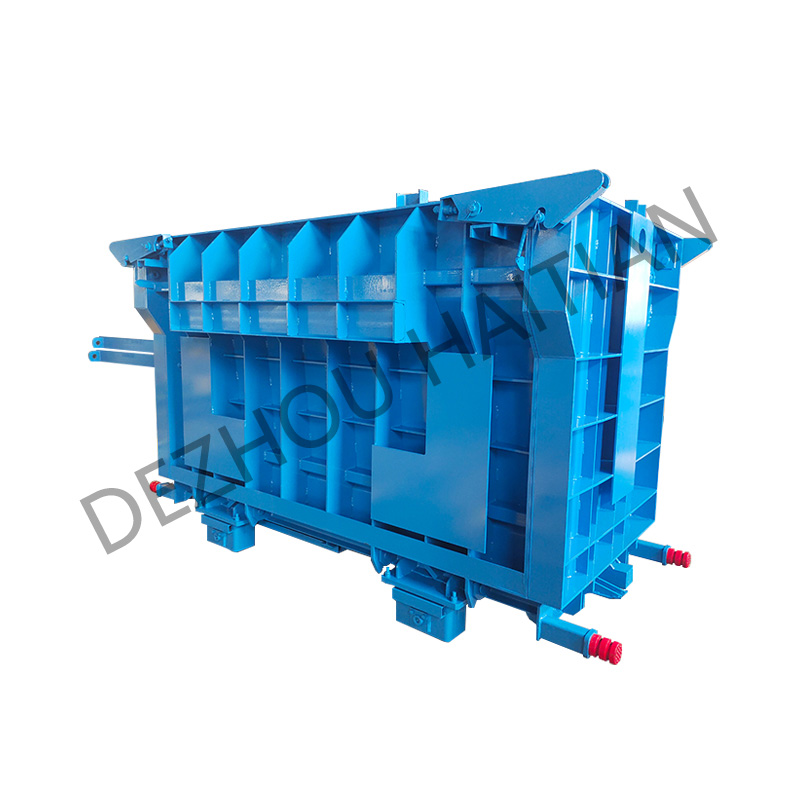

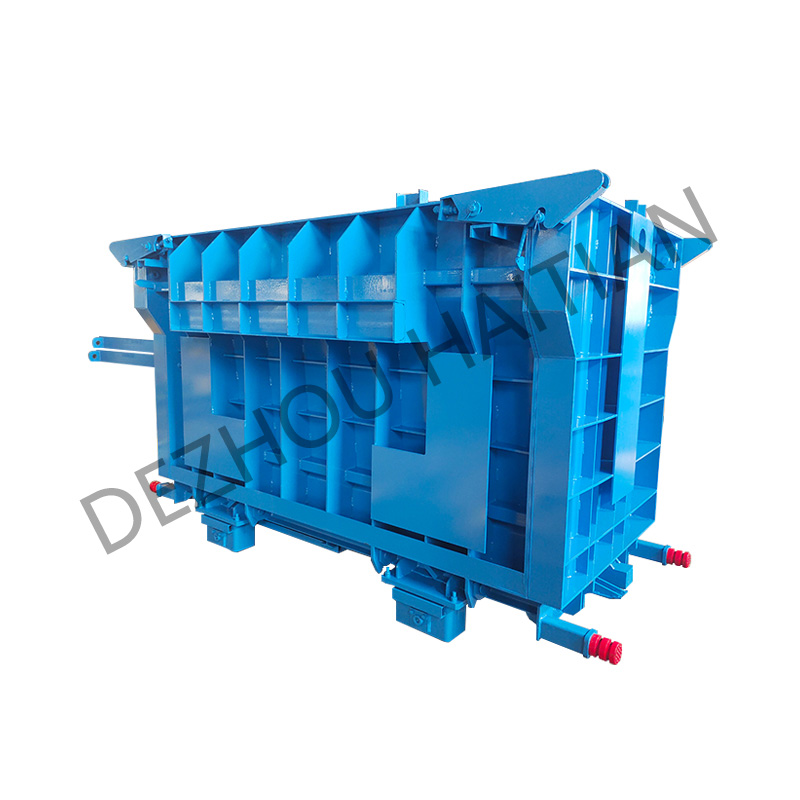

Precast Concrete Jersey Barrier Mould

1.Durable heavy steel construction ensures long service life and consistent casting performance

2.Precision machined cavities deliver uniform barrier geometry and reliable alignment

3.Modular insert system enables flexible production layouts and quick tooling changeover

4.Smooth cavity finish promotes fast demoulding and excellent surface quality

5.Low maintenance design reduces downtime and simplifies on site servicing

6.Optimized cavity design enhances material efficiency and minimizes waste

Product overview and summary

The Precast Concrete Jersey Barrier Mould is engineered to deliver precise forming and efficient demoulding for highway and site safety applications. This product integrates robust fabrication with refined cavity finish to produce uniform barrier units suitable for a wide range of installation scenarios. The design supports modular production flows and straightforward handling procedures while maintaining consistent quality and repeatable geometry.

Function and introduction

As a forming system, the Precast Concrete Jersey Barrier Mould shapes continuous barrier profiles with smooth faces and exact mating surfaces. It is introduced as a factory ready solution that adapts to precast yards and on site casting environments, offering predictable output and simplified logistics for barrier production.

Usage scheme and handling

Recommended usage schemes pair the mould with conventional casting practice and basic handling fixtures to streamline casting cycles and ease demoulding steps. The modular insert approach allows rapid adaptation of cavity arrangement to suit different project requirements without complicated retooling or lengthy downtime.

.

Features and parameters

Key features include heavy duty steel framing, precision machined mating surfaces, and polished cavity interiors that reduce adhesion and preserve concrete detail. Parameters are offered as configurable options covering cavity geometry, connection interfaces, and surface treatment choices to match varied concrete mixes and finish expectations.

Advantages and performance benefits

Main advantages center on dimensional repeatability that simplifies site installation, a maintenance friendly layout that reduces operational interruptions, and optimized cavity design that conserves material and reduces waste. The mould enhances demoulding speed and produces consistent surface texture that meets demanding project standards

.

Applications and use cases

Application scenarios include highway median installation, temporary traffic control systems, urban segregation elements, and factory supplied safety barriers for infrastructure projects. The mould is suitable for both centralized precast production and distributed on site casting operations, enabling versatile deployment across project types.

Customer feedback and testimonials

Clients consistently report reliable barrier geometry, high quality surface finish, and reduced production intervention when the mould is integrated into existing workflows. Field feedback highlights improved throughput, easier installation of cast units, and fewer rejects during continuous production cycles.

Company capability and service support

The manufacturer provides comprehensive fabrication capability, engineering consultation, and field service to support installation and commissioning. Technical assistance covers cavity specification, handling recommendations, and spare part provisioning to sustain uninterrupted production.

Reliability and quality assurance

Reliability is assured through controlled fabrication practices, careful welding and machining checks, and validation trials that confirm performance in working conditions. Quality assurance routines emphasize fit accuracy, surface integrity, and lasting alignment to guarantee consistent casting results.

Final summary of product advantage

Overall, the Precast Concrete Jersey Barrier Mould represents a practical and durable choice for producers focused on dependable barrier casting and efficient production management. Its balance of sturdy construction, adaptable design, and proven field reliability makes it a valuable asset for operations seeking to enhance quality, streamline workflows, and improve installation outcomes.