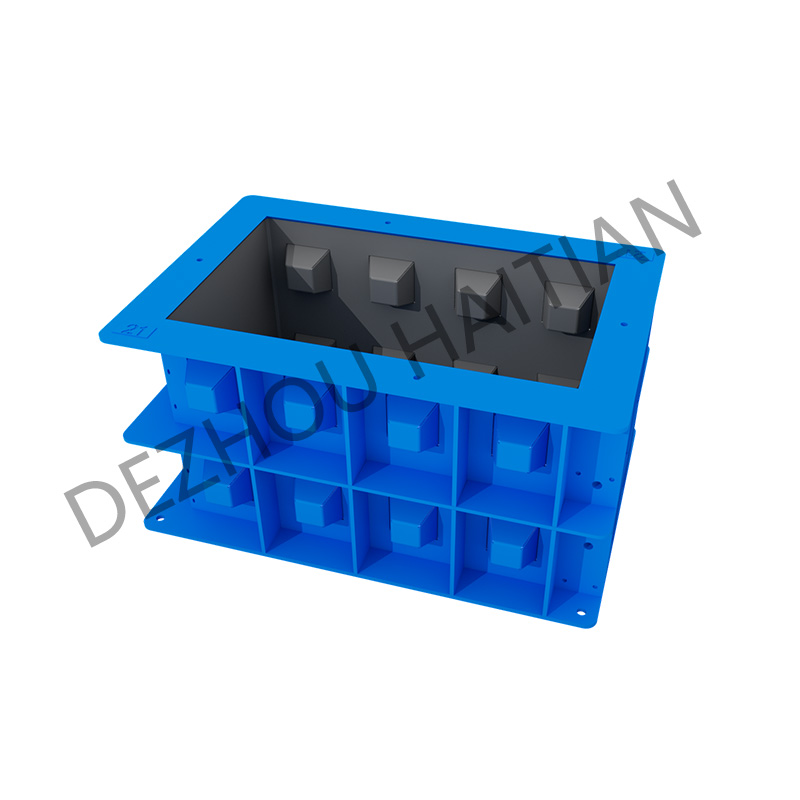

Precast Concrete Block Mould

1.Superior durability from heavy steel construction for extended service life

2.Precision engineering for consistent block dimensions and reliable interlock

3.Modular design enabling flexible production layouts and easy reconfiguration

4.Smooth internal surfaces for fast demoulding and improved finished quality

5.Low maintenance structure that minimizes downtime and reduces operating cost

6.Efficient casting performance that reduces material waste and increases yield

Product Detail — Precast Concrete Block Mould

Summary of function and introduction

The Precast Concrete Block Mould is a precision forming solution designed to deliver consistent block geometry and efficient demoulding for industrial precast workflows. Its primary function is to shape interlocking and stackable concrete elements while enabling streamlined casting and handling schemes. The introduction highlights robust steel construction, polished cavity surfaces, and modular coupling options. Usage schemes include seamless integration with existing casting lines and flexible layout arrangements for varied production demands. Key features cover durable frame design, accurate alignment systems, easy release surfaces, and adaptable cavity configurations. Parameters focus on material selection, surface finish, cavity geometry, and interface compatibility. Advantages include improved dimensional stability, reduced maintenance needs, enhanced release performance, and optimized material use. Typical applications span civil infrastructure, retaining and barrier systems, agricultural containment, and precast yard supply. Customer feedback praises repeatable quality and long service life. Company strength is evident in manufacturing capacity, technical support, and field service. Reliability is established through controlled fabrication processes and validated on site performance. In conclusion, the Precast Concrete Block Mould offers a practical, durable, and efficient platform for modern precast producers seeking consistent results and lower operating burdens.

Function and introduction

The mould functions as a reliable forming tool that enforces exact cavity profiles and low friction interfaces for smooth casting cycles. The product introduction emphasizes compatibility with normal precast workflows and the ability to adapt cavity layout to project needs.

Usage schemes and handling

Usage schemes encourage pairing the mould with standard casting practices and simple handling fixtures to allow quick changeover of cavity inserts and consistent throughput. The modular approach supports rearrangement for different product types without complex retooling.

Features and parameters

Features include hardened steel framing, precision machined mating surfaces, and polished cavity interiors that reduce adhesion. Parameters are presented as customizable options covering cavity shape, connection style, and external mounting arrangement to match material mixes and site preferences.

Advantages and performance benefits

Advantages concentrate on improved dimensional repeatability that simplifies downstream installation, reduced service intervention due to robust design, and material efficient cavities that lower waste and enhance yield.

Applications and use cases

Applications cover municipal construction projects, coastal and erosion control installations, farm containment systems, and factory supplied precast components for building works. The mould suits both on site production and centralized precast yards.

Customer feedback and testimonials

Client reports emphasize consistent interlock performance, durable surface finish of cast units, and minimal downtime during continuous operation. Field feedback also notes clear improvements in productivity and reduced rejection rates.

Company strength and service support

The manufacturer provides an integrated offering with workshop fabrication, engineering consultation, and on site commissioning support. Post sale service covers troubleshooting guidance and spare part supply to maintain continuous production.

Reliability and quality assurance

Reliability is backed by careful welding practices, precision machining checks, and practical trials that validate performance under real world conditions. Inspection routines ensure every unit meets the declared fabrication standards.

Final summary of product advantage

Overall, the Precast Concrete Block Mould represents a balanced investment for producers focused on repeatable quality and efficient casting workflows. Its combination of durable construction, adaptable design, and proven field reliability makes it a strong choice for modern precast operations.