Precast Concrete Wind Power Tower Mould

1.Durable heavy steel construction ensures long service life and stable segment geometry

2.Precision machined segments provide consistent joint fit and reliable on site assembly

3.Modular segment design allows flexible production layouts and simplified cavity replacement

4.Polished cavity surface promotes superior concrete finish and efficient demoulding

5.Low maintenance engineering minimizes downtime and simplifies routine servicing

6.Optimized mould profile enhances material efficiency and reduces concrete waste

Overview and summary

The Precast Concrete Wind Power Tower Mould is engineered to produce precise tower segments with consistent geometry and smooth surface finish. Its core function is to enable reliable segment casting that supports efficient joint fit and predictable site assembly. This introduction covers typical use schemes, distinguishing features, configurable parameters, main advantages, application scenarios, customer feedback, company capability, and proven reliability. In summary, the Precast Concrete Wind Power Tower Mould combines durable construction and flexible configuration to deliver repeatable casting quality and streamlined production workflows.

Function and introduction

Designed as a segment forming system, the Precast Concrete Wind Power Tower Mould enforces exact cavity profiles and controlled surface texture to help fabricators achieve reliable mating joints and consistent aerodynamic surfaces. The mould suits both centralized precast yards and modular on site casting setups, offering compatibility with common handling and curing practices.

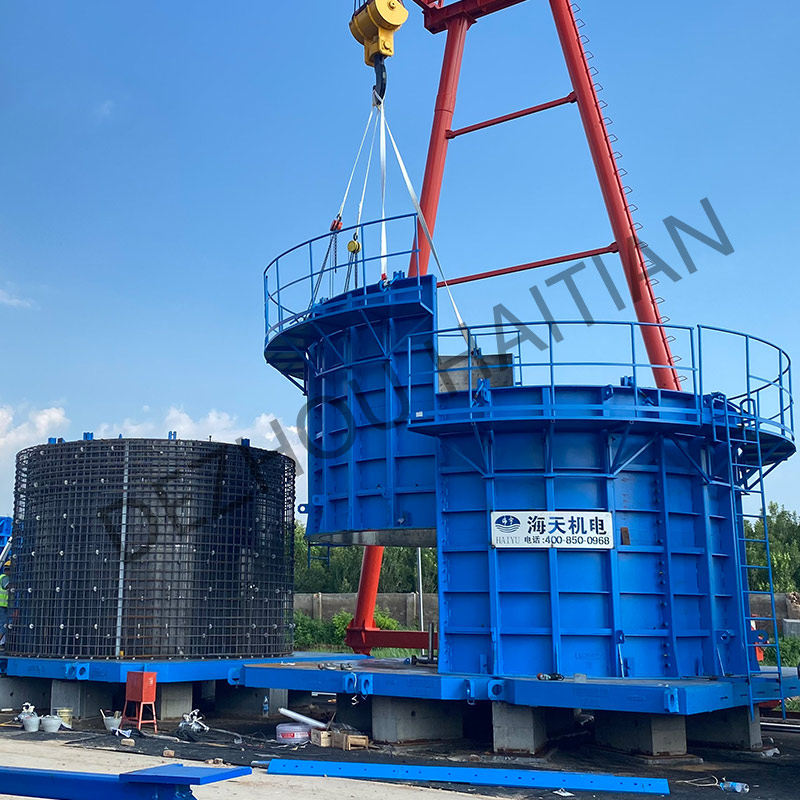

Usage scheme and handling

Recommended use schemes integrate the mould with established casting beds and simple handling fixtures for safe pouring and gentle demoulding. The modular segment approach allows quick replacement of wear parts and easy reconfiguration of cavity inserts to match project specific tower geometry without complex tooling overhaul.

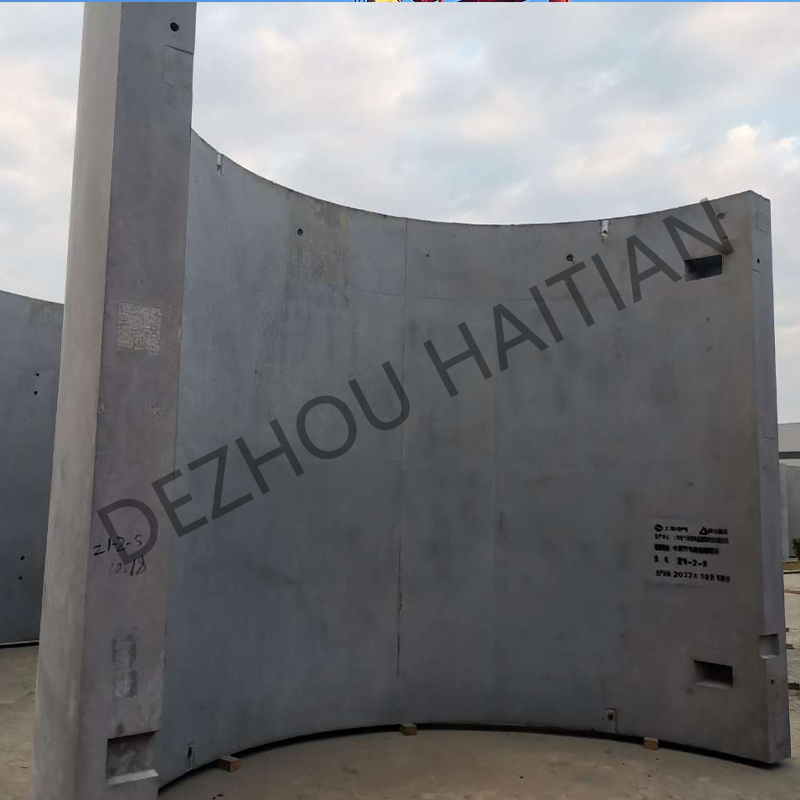

Key features and configurable parameters

Core features include heavy duty steel framing, precision machined mating surfaces, polished cavity interiors, and modular coupling points for handling equipment. Parameters are presented as selectable options covering cavity profile, interface style, surface treatment, and mounting arrangement to suit different concrete mixes and finish expectations.

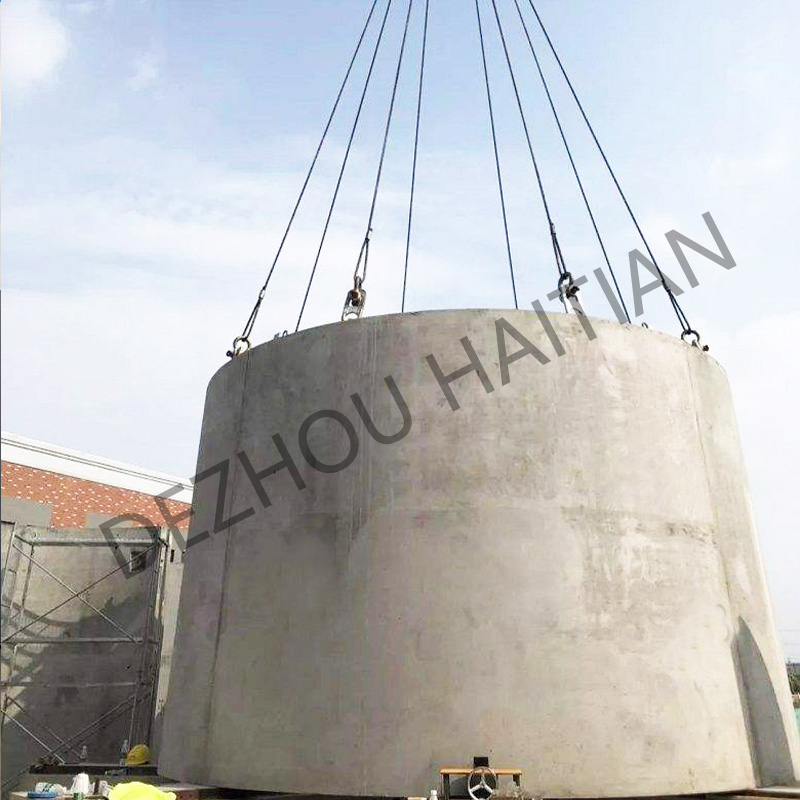

Advantages and performance benefits

Primary advantages focus on dimensional stability that aids rapid segment assembly, low maintenance layout that reduces stoppages, and optimized cavity design that improves material efficiency. The mould supports smooth demoulding and consistent surface detail that helps minimize finishing work and simplifies site installation.

Applications and use cases

Application scenarios include production of tower segments for onshore and offshore wind installations, manufacturing of tapered cylindrical elements for renewable energy projects, and fabrication of structural sections for related infrastructure. The mould adapts well to precast yards that supply segments to assembly sites and to contractors who prefer near site casting.

Customer feedback and testimonials

Clients report steady joint alignment and dependable surface finish when the mould is adopted in controlled workflows. Feedback commonly highlights improved fit between adjacent segments, easier installation at assembly points, and reduced rework compared to earlier forming methods.

Company capability and service support

The manufacturer offers integrated fabrication capability, engineering consultation, and field service to assist with mould specification and commissioning. Technical support covers cavity design optimization, handling recommendations, and spare part provisioning to help maintain uninterrupted production.

Reliability and quality assurance

Reliability is assured through disciplined fabrication practices, precision machining checks, and practical trial casting that validate performance under working conditions. Quality assurance routines emphasize fit accuracy, surface integrity, and alignment verification to ensure consistent casting output over extended service life.

Final summary of product advantage

Overall, the Precast Concrete Wind Power Tower Mould represents a robust and adaptable solution for producers focused on repeatable segment quality and efficient production management. Its combination of precision engineering, modular flexibility, and verified field reliability makes it a compelling choice for fabricators and contractors in the wind power sector.