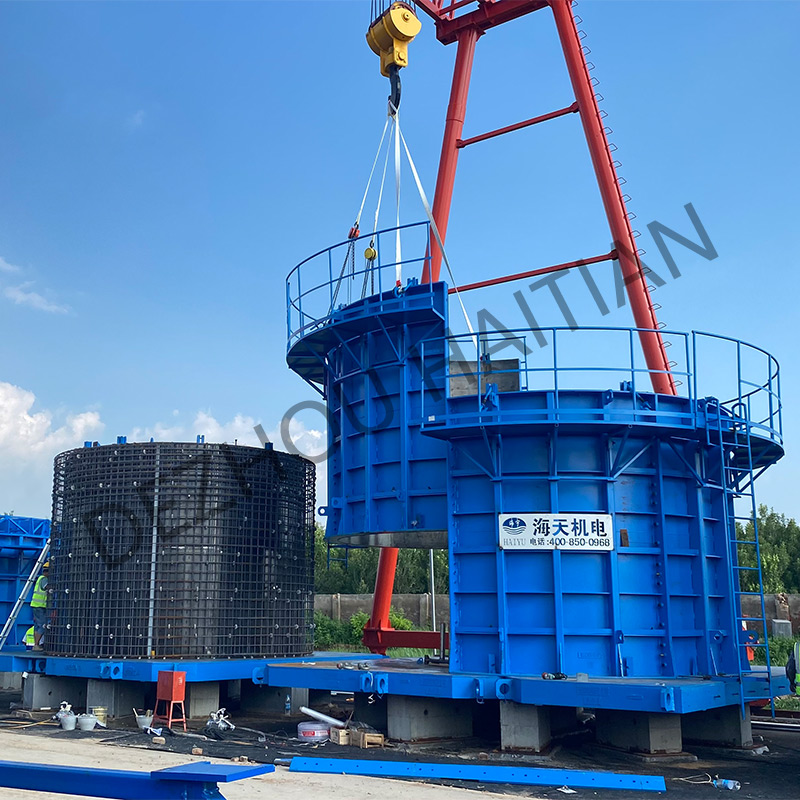

Precast Concrete Wind Tower Segment Mold for Wind Turbine Towers

1. Fits Project Drawings: The mold can be customized to match tower section geometry, reinforcement layouts, and embedded parts per engineering drawings, meeting site requirements.

2. Optional Vibration for Concrete: Vibration solutions enable uniform compaction, improving the internal density and exterior finish of tower segments.

3. Stable Curing Support: Heating and controlled curing maintain stable temperatures, aiding concrete strength development in harsh climates.

4. Designed for Large Towers: The mold withstands heavy-duty wind tower production, ensuring accuracy during repeated casting cycles.

5. Modular & Transport-Friendly: Segmented parts and standardized connections simplify assembly, shipment, and integration for precast plants.

6. Easy Operation & Maintenance: User-friendly access, logical component layout, and readily available spare parts reduce downtime.

As wind energy projects continue expanding into regions with diverse terrain and demanding construction timelines, reliable precast solutions have become essential. The Precast Concrete Wind Tower Segment Mold for Wind Turbine Towers is designed for manufacturers who need dependable forming equipment that can keep pace with the growing global wind industry. It offers a balance of structural rigidity, customization flexibility, and practical day-to-day usability, helping factories deliver tower components with consistent geometry and smooth finish. Instead of treating the mold as a static piece of hardware, the system works more like a production companion—supporting workshop rhythm, minimizing disruptions, and maintaining precision even through long casting cycles.The structure can be adapted to different tower diameters, segment lengths, reinforcement layouts, and embedded steel details, giving engineering teams the freedom to preserve original design intent. Optional vibration and controlled curing support help stabilize mix quality and early strength development, especially when the workshop environment fluctuates with the seasons. Thoughtful modularity makes transport and installation easier, while service-friendly access points reduce maintenance pressure on production teams. With its blend of durability and practicality, the Precast Concrete Wind Tower Segment Mold for Wind Turbine Towers provides manufacturers with a reliable foundation for producing high-performance tower sections efficiently and confidently.

1. Customization That Respects Engineering Intent

Wind tower designs vary widely across regions and project scales, and each carries its own structural goals. The Precast Concrete Wind Tower Segment Mold for Wind Turbine Towers adapts to these needs without pushing designers toward compromise. Segment geometry, reinforcement patterns, internal inserts, and door openings can all be aligned with project drawings. This flexibility allows production teams to maintain the structural and aerodynamic requirements defined by the engineering consultant. Instead of forcing the project to fit the mold, the mold quietly adjusts itself to the project, ensuring every tower segment feels purpose-built rather than mass-produced.

2. Concrete Compaction Assistance for a Better Finish

Concrete tower segments require a level of uniformity that is difficult to achieve without proper compaction. For workshops that prefer additional support, the mold accepts optional vibration systems that enhance material consolidation. With steadier compaction, concrete settles more uniformly around dense reinforcement cages, reducing surface blemishes and improving the density of the finished structure. This optional feature does not overwhelm the workflow; instead, it integrates naturally into daily casting routines, giving operators a simple, dependable way to elevate product consistency whenever required.

3. Reliable Curing Stability in Shifting Environments

Temperature swings can challenge even the most experienced precast team, especially when producing large tower components. To help stabilize early strength development, optional heating and controlled curing systems can be integrated into the mold. These functions support more predictable hardening conditions, giving manufacturers confidence even when the workshop operates in cold seasons or humid coastal regions. Rather than relying on trial-and-error approaches, the mold offers steady thermal behavior that keeps production schedules from drifting off-course.

4. Built to Support the Demands of Large Tower Production

Producing wind tower segments places significant stress on forming equipment due to heavy reinforcement, high concrete volumes, and frequent lifting operations. The Precast Concrete Wind Tower Segment Mold for Wind Turbine Towers is structured to withstand these challenges. Its reinforced frame and joint configuration maintain shape stability over repeated casting cycles, helping each segment emerge with dependable geometry. Operators can work without worrying about alignment drift or deformation, which contributes to smoother downstream tasks such as segment stacking, alignment, and grouting.

5. Modular Layout That Simplifies Transport and Integration

Transporting and installing large molds is often a logistical puzzle. To ease this pressure, the system uses a modular layout with segmented panels and standardized connection points. This approach allows the mold to be shipped in manageable sections, assembled on-site with predictable workflows, and integrated smoothly into existing precast lines. Whether a factory is upgrading capacity or introducing wind tower components for the first time, the modular design reduces interruption and protects production availability.

6. Thoughtful Operation and Maintenance Experience

Daily operation plays a large role in how a mold performs over its service life. The Precast Concrete Wind Tower Segment Mold for Wind Turbine Towers includes user-friendly lifting lugs, accessible maintenance areas, and a structural layout that supports routine inspections without unnecessary disassembly. Spare parts follow common standards so workshops do not need to manage an overly complex inventory. This attention to practical details helps teams maintain a steady pace, reducing downtime and improving the confidence of operators who work with the system every day.

7. A Practical Choice for Modern Wind Energy Manufacturing

The global wind industry moves quickly, and manufacturers need equipment that can keep up without adding operational strain. With its blend of customization, structural strength, curing support, and service convenience, the Precast Concrete Wind Tower Segment Mold for Wind Turbine Towers fits naturally into the demands of contemporary tower production. It supports consistent output, cleaner surfaces, safer workflows, and more predictable schedules—making it a steady partner for factories preparing components for long-term wind power installations.