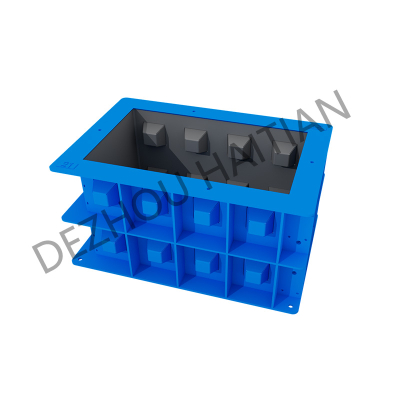

Precast Bridge Beam Mold

1.Customizable to project drawings:The mold is built to follow your drawings so beam sections and embed positions match site requirements without forcing design changes.

2.Optional vibration and compaction support:The system accepts vibration options to help concrete consolidate evenly and improve surface finish and structural integrity.

3.Optional thermal and curing aids:Heating and controlled curing options are available to stabilize early strength development when ambient conditions demand it.

4.Purpose made for bridge beam production:Components and joints are designed for repeated heavy use so finished beams keep reliable geometry and handle postcasting operations with ease.

4.Modular design for easy integration:Panelized sections and standard connection points make the mold simple to transport, assemble, and align with existing precast lines.

5.User-friendly operation and maintenance:Accessible service points, clear lifting interfaces, and standardized spare parts reduce downtime and simplify everyday upkeep.

A well-designed Precast Bridge Beam Mold becomes more than a piece of equipment on the production floor—it acts like a steady partner that quietly supports each stage of precast girder manufacturing. This mold is built to respond to the diverse needs of bridge projects, where section precision, dependable strength and repeatable accuracy matter far more than anything else. Whether the beams are meant for highways, municipal structures or long-span crossings, the mold provides a reliable foundation that keeps your design intention intact while easing the challenges that usually appear during casting.By adapting closely to project drawings, the Precast Bridge Beam Mold helps contractors and engineers keep full control over geometry and embedded components. Its structure welcomes optional features such as compaction aids or curing support, allowing the mold to fit into both basic and advanced production environments. The steel body is shaped and reinforced for repeated daily use, ensuring that every girder emerges with stable dimensions and clean edges. At the same time, its modular format keeps transportation, alignment and integration surprisingly straightforward, even during busy production seasons.The Precast Bridge Beam Mold also considers the human side of factory work. With accessible service areas, clear lifting points and standardized components, operators do not have to fight the equipment to complete routine tasks. This combination of precision, readiness and ease of use makes the mold a dependable solution for companies that want to deliver consistent beam quality while keeping production smooth and predictable. Across a range of climates, project sizes and technical requirements, the Precast Bridge Beam Mold remains a practical companion that helps bridge projects move from drawing boards to real-world structures with confidence.

1.Adaptability Rooted in Your Drawings

Every bridge project begins with a vision, and the Precast Bridge Beam Mold is shaped to respect that vision rather than force changes. It follows your drawings with care, mirroring the exact geometry of each section and positioning embedded items where they belong. This faithful adherence to the original concept ensures that the mold never becomes a limitation. Instead, it behaves like a translator between design and construction, capturing subtle details and carrying them into the physical beam without distortion. This flexibility becomes especially valuable on complex projects where alignment, prestressing layouts and embedded parts must work in perfect harmony.

2.Support for Smooth Compaction and Cleaner Finishes

Concrete behaves best when it settles evenly, and the mold embraces optional compaction support to help achieve this. By accepting vibration systems, the Precast Bridge Beam Mold minimizes air pockets and guides the concrete into a dense, uniform mass. The resulting beams carry a cleaner appearance and stronger internal structure, reducing the variability that often troubles large precast elements. With smoother surfaces and well-consolidated cores, the beams require less post-processing, which allows production teams to redirect their time to other important tasks.

3.Assistance for Stable Early-Age Curing

Weather seldom cooperates during busy production schedules, yet the Precast Bridge Beam Mold offers optional thermal and curing aids to maintain consistency. When temperatures dip or humidity shifts, these aids create a more predictable environment for strength development. By supporting steady curing, the mold helps beams reach reliable performance levels even during demanding seasons. This steady control not only protects the quality of the beams but also offers producers the reassurance that deadlines do not need to bow to the weather.

4.Strength and Reliability for Bridge-Grade Production

The life of a bridge beam mold is rarely gentle. It must tolerate heavy reinforcement cages, dense concrete, continuous lifting and repetitive cycles. For this reason, the Precast Bridge Beam Mold is built with a structure that favors longevity. Reinforced walls, well-secured joints and carefully designed connections help the mold withstand repeated casting sessions without drifting from its intended geometry. The mold maintains alignment through stresses that would gradually distort less robust equipment. This stable performance pays off in the form of beams that match required tolerances and handle subsequent operations—such as tensioning, lifting and storage—without issue.

5.Modular Organization for Efficient Integration

Factories often adjust their production lines as projects evolve, and the mold respects that need for flexibility. The Precast Bridge Beam Mold uses a panelized layout with standardized connection points, which makes relocation, assembly and alignment surprisingly smooth. It can fit into existing production lines without long downtimes and can expand into new configurations whenever project scopes shift. Transportation also becomes easier, as the modular structure breaks down into manageable sections that maintain strength without becoming cumbersome.

6.Designed for Comfortable Daily Operation

Operators interact with the mold every day, and the small details influence productivity more than most people realize. The Precast Bridge Beam Mold incorporates thoughtful features that ease daily work: accessible service areas for cleaning and inspection, clear lifting points that remove guesswork during crane operations and standardized spare parts that make maintenance quick instead of tedious. These conveniences shorten setup times and reduce interruptions, smoothing out the daily rhythm of factory operations. When equipment respects the way people work, production flows naturally, and downtime becomes a rare visitor.