The Texas Haitian Factory Produces Pipe Gallery Molds.

Concrete pipe gallery molds: The core supporting element in the construction of urban underground pipe galleries

In the construction of urban underground integrated pipe galleries, concrete pipe gallery molds serve as the core forming tools, directly determining the quality, construction efficiency, and engineering durability of the pipe gallery components. With the acceleration of urbanization and the upgrading of underground infrastructure construction in China, concrete pipe gallery molds have evolved from traditional simple tools to specialized equipment with integrated precision manufacturing and intelligent control, becoming a key link in ensuring the quality of pipe gallery projects.

The core function of concrete pipe gallery molds is to shape the concrete into pipe gallery components that meet design requirements, including the base plate, side walls, roof plate, and overall box structure. Compared to ordinary concrete molds, their significant features include large specifications, strong bearing capacity, and high precision requirements. They must also meet multiple requirements such as structural stability, waterproof sealing, and reusability. In the comprehensive pipe gallery projects where multiple types of pipelines are concentratedly laid, the quality of the molds directly affects the service life and operational safety of the pipe gallery. High-quality molds can extend the service life of the pipe gallery structure to over 100 years.

According to different engineering requirements, concrete pipe gallery molds can be divided into various types. Based on materials, steel molds are currently the mainstream, made from Q345 high-strength steel through CNC cutting and welding, featuring high rigidity, small deformation, and a large number of reuse times (up to over 300 times). Plastic molds use polypropylene as the main raw material, being lightweight and low in cost, suitable for small branch pipe galleries or temporary projects, but with a shorter lifespan, generally not exceeding 50 times. Fiberglass molds are widely used in pipe gallery projects in coastal areas with high salt spray or in chemical industrial parks due to their excellent corrosion resistance. According to the construction method, they can be divided into prefabricated molds and cast-in-place molds. The prefabricated molds are produced in factories with standardized pipe gallery components and then transported to the site for assembly, significantly shortening the construction period and becoming the mainstream mode of modern pipe gallery construction.

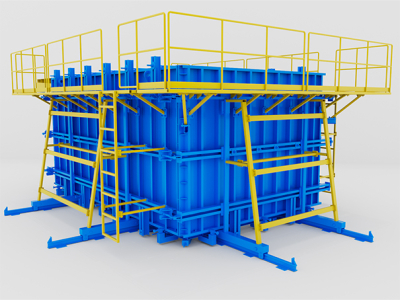

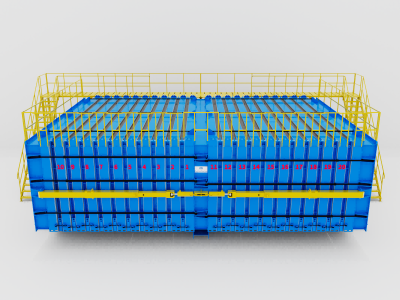

A complete set of concrete pipe gallery mold systems consists of multiple key components. Taking the commonly used box-type pipe gallery prefabrication molds as an example, their structure includes the base plate guide wall template, box-type inner template, outer template, top plate template support frame, connection and fastening system, and demolding device. The base plate guide wall template, as the basic component, needs to ensure sufficient strength to withstand the pressure of concrete pouring; the inner template adopts a modular design and can adapt to different cross-sectional dimensions of pipe galleries through adjustment mechanisms; the outer template surface is polished to ensure the smoothness and flatness of the concrete components; the connection system uses high-strength bolts and positioning pins to ensure that the assembly accuracy error is controlled within 2mm. Some high-end molds also integrate intelligent monitoring devices to monitor temperature and pressure changes during the pouring process.

The manufacturing and application of concrete pipe gallery molds involve multiple key technologies. During the mold design stage, BIM technology is combined for three-dimensional modeling to simulate assembly and pouring processes, allowing for the early avoidance of structural conflicts; the processing stage uses precision processing technologies such as laser cutting and CNC milling to ensure that the gap between the templates is less than 0.5mm, preventing leakage of concrete; the sealing technology is the core difficulty, using a combination of water-expanding rubber strips and steel edges to effectively solve the leakage problem during concrete pouring; the demolding technology uses a hydraulic pushing device and demolding agent to achieve non-destructive demolding of the components, improving the yield rate. In a provincial capital city's underground pipe gallery project, after adopting intelligent steel mold prefabrication technology, the production efficiency of pipe gallery components increased by 40%, and the scrap rate dropped to below 0.5%.

The application value of concrete pipe gallery molds not only lies in the improvement of construction efficiency, but also has significant importance for project quality and later operation and maintenance. The pipe gallery components formed by high-quality molds have precise dimensions and small joints, reducing the amount of waterproof treatment work and lowering the risk of later leakage; The standardized molds for production have strong interchangeability, which provides convenience for later maintenance and replacement. At the same time, the upgrade of mold technology promotes the green development of pipe gallery construction. The reused steel molds reduce the consumption of wood, and the factory prefabrication mode reduces dust and noise pollution at the construction site.

In the future, the molds for concrete pipe galleries will develop towards intelligence, light weight, and multi-functionality. With the maturity of 3D printing technology, the production cycle of personalized customized molds will be significantly shortened; intelligent molds will integrate more sensors and automatic control units to achieve full automation of pouring, curing, and demolding processes; the application of new composite materials will reduce the weight of molds while ensuring strength, and improve the transportation and assembly efficiency. As the core equipment for pipe gallery construction, the continuous innovation of concrete pipe gallery mold technology will surely provide a more solid support for the high-quality development of urban underground infrastructure construction in our country.