Solution For Fixed Bed Of Concrete Components

The Foundation of Industry Transformation

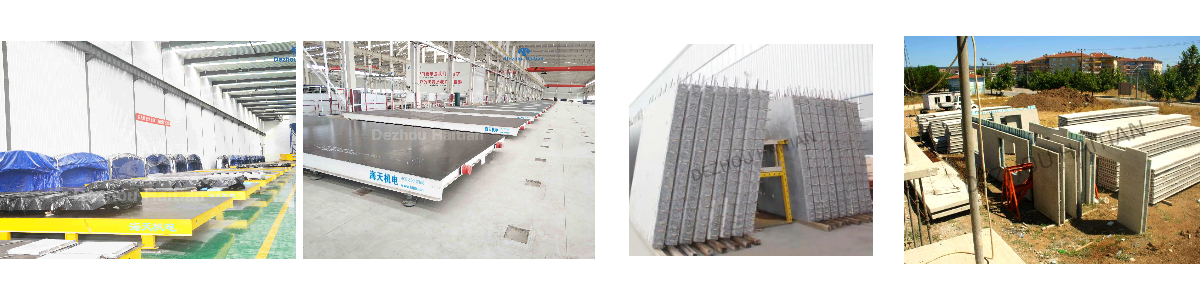

At a crucial stage where the global construction industry is moving towards more efficient and sustainable development, the prefabricated concrete technology is undergoing an unprecedented transformation. As the core production equipment for this transformation, the design concept and technological innovation of the concrete component fixation bed directly determine the production capacity limit, product quality and market adaptability of the prefabrication factory. The traditional single-function, fixed-size production platform has been unable to meet the market demands for the diversity, customization and rapid delivery of components. Now, a revolution centered on "modularization" and "adaptability" is reshaping the future landscape of the concrete component fixation bed, providing unprecedented flexibility for the production of various products ranging from standardized wall panels to complex irregular components.

The paradigm shift from rigid production to flexible manufacturing

The Limitations and Challenges of the Traditional Model

For a long time, prefabricated concrete factories have relied on fixed production platforms specifically designed for a single product. These dedicated concrete component beds, although reliable in their specific tasks, have also fixed the production line. When market demands shift to new component sizes, shapes, or require the simultaneous production of multiple products, the factories often face costly renovation expenses, lengthy production halts, and significant losses in production capacity. This rigid production model has become a major bottleneck restricting enterprises' response speed and economic benefits in today's highly volatile market environment.

The introduction of the flexible manufacturing concept

The new generation of concrete component fixed-bed solutions, with its core idea shifting from "designing equipment for the product" to "adapting the equipment to the product", is not a simple improvement of the traditional platform, but a fundamental shift in design philosophy. By introducing advanced modular concepts, the fixed bed is no longer an inseparable whole but consists of a series of standardized, reconfigurable functional modules. These modules are like building blocks, allowing the factory to quickly adjust the size, boundaries, anchor point positions, and even the layout of the curing system of the platform according to the drawings of the components to be produced, thus achieving true flexible manufacturing. This adaptability ensures that the same set of concrete component fixed-bed system can serve a wider range of product catalogs, maximizing asset utilization.

The core advantages and applications of modular design

Achieving rapid model change and product diversification

The most significant advantage of the modular concrete component fixed bed is its astonishing speed of model change. Through the pre-processed connection interfaces and positioning systems, operators can use workshop cranes or specialized tools to complete the reconfiguration of the production line in a very short time. This means that the factory can switch from producing large exterior wall panels in the morning to producing balcony panels or stair components in the afternoon on the same production line. This capability makes the production mode of small and medium batch sizes and multiple varieties economically feasible, allowing enterprises to undertake more diverse projects without investing in multiple dedicated production lines.

Improving Space Utilization and Factory Planning Efficiency

In the context of increasingly scarce land resources and high construction costs for factories, modular design has significantly enhanced the efficiency of factory space utilization. The adaptable concrete component fixed beds can create higher output within the same area through compact layouts and shared curing areas. At the same time, its flexibility also provides more possibilities for the overall process planning of the factory. The material flow routes, steel bar installation stations, concrete pouring and component demolding areas can all be optimized based on the variable concrete component fixed beds, thereby forming more smooth and efficient production units.

Supporting technological innovation and process upgrading

The modular architecture opens the door for continuous technological upgrades. For instance, when new sensor technologies, automatic vibrating equipment, or energy-saving curing covers are developed, the factory can integrate them as new functional modules into the existing concrete component fixation bed system without having to replace the entire platform. This "future validation" design concept protects the long-term investment of the enterprise, ensuring that the production equipment can continuously evolve with technological progress and always remain competitive.

The deep integration of adaptive technologies

Intelligent control systems and digital twins

The essence of the modern adaptive concrete component fixed bed lies in its intelligent control system. This system is connected to the central production management system of the factory and can receive product data from the design software. When a new component task is issued, the system can automatically generate the optimal bed configuration plan and guide the execution agency or manual operation for the switch. Further, by combining with digital twin technology, the factory can pre-simulate the entire production process in a virtual environment, verify the configuration plan of the concrete component fixed bed, optimize the production process, thereby avoiding risks before actual production and improving the success rate for the first time.

Multifunctional interfaces and integrated accessories

To achieve true "multiple uses from one bed", the new generation of concrete component fixation beds is designed with a rich set of standardized mechanical and electrical interfaces. These interfaces enable the quick installation and connection of various functional accessories, such as core extraction pipe supports for producing prestressed hollow floor slabs, side mold locking devices for producing sandwich insulation wall panels, or surface embossing templates for producing decorative components. This high degree of integration allows a single platform to cover a wide range of production from structural components to architectural decorative components.

The profound impact on the future industry ecosystem

Promoting design freedom and architectural innovation

When the production end is no longer a constraint, architectural designers will have greater creative freedom. The adaptable concrete component fixed bed enables the production of concrete components with complex geometries and personalized facades, which is cost-effective. This will stimulate more architectural innovation, push precast concrete from behind to the forefront, and make it a key material for expressing architectural aesthetics, rather than just hidden structural components.

Promoting the optimization of the supply chain and regionalized production

Modular and adaptive technologies have lowered the initial barriers and risks of establishing an efficient prefabrication factory. It makes it more economical to establish medium-sized, multi-functional regional prefabrication factories in different regions. These factories can quickly respond to the specific needs of local projects, reduce long-distance transportation, and thereby optimize the carbon footprint and response speed of the entire construction supply chain. The concrete component fixed beds, as the core of these regional factories, are characterized by their flexibility, which is the key to the success of this business model.

Shaping Sustainability and Circular Economy

From a life-cycle perspective, modular and adaptable concrete component fixed beds are themselves exemplary of sustainable design. Their long service life and upgradeable features reduce equipment obsolescence and resource consumption. At the same time, it enables factories to produce building components with higher precision, better quality, and longer lifespan, thereby extending the overall lifespan of the building. Moreover, the flexible production capacity also helps to utilize sustainable materials such as recycled aggregates to produce specific components, providing technical support for the practice of circular economy in the field of architecture.

Embrace flexibility, define the future

The future of the precast concrete industry will undoubtedly belong to those enterprises that can respond to the myriad demands of the market with the fastest speed, the highest quality, and the most cost-effective manner. The modular and highly adaptable concrete component fixed-bed solution is precisely the key bridge leading to this future. It goes beyond the simple production of tools and evolves into a strategic production system, embedding manufacturing flexibility deeply into the hardware foundation of the factory.

For industry participants, investing in such technologies is not merely about upgrading equipment; it is also about investing in a core capability to deal with uncertainties. It means that enterprises are no longer defined by fixed production lines but can actively define their product boundaries and market opportunities. When the fixed-bed concrete structures become intelligent and flexible, the potential of prefabrication technology can truly be fully realized, and with solid innovation, it can shape the appearance of our future world.