Key Considerations for Selecting Durable Precast Wall Panel Molds

In the global trend of industrialization in the construction industry, the selection of prefabricated wall panel molds has become a crucial strategic decision that determines the success or failure of a project. It is not merely the procurement of a simple production tool; rather, it is a deep investment in the long-term quality, economic benefits, and construction efficiency of the project. A durable mold system is the foundation for ensuring that prefabricated concrete components achieve excellent precision, excellent surface quality, and excellent long-term performance. This article aims to provide a comprehensive guide for developers, contractors, and prefabrication manufacturers, analyzing the key factors to be weighed when choosing durable prefabricated wall panel molds from multiple core dimensions.

Key consideration: Beyond initial cost, focus on the full life cycle value

The primary principle for choosing molds is to adopt a perspective of the full life cycle cost. The most competitive initial price does not necessarily indicate the best long-term investment. A high-quality and durable prefabricated wall panel mold, although the initial investment may be higher, its stability, low maintenance requirements, and the ability to continuously produce high-quality components over hundreds or even thousands of production cycles will significantly reduce the unit cost per piece and avoid project delays and quality risks caused by mold failure. Investors should evaluate the total cost of ownership of the mold within the expected production volume, rather than merely focusing on the purchase price.

Materials Science and Manufacturing Processes: The Physical Foundation of Durability

The durability of molds is directly rooted in their materials and manufacturing processes. When making a choice, one must thoroughly examine the material grades and characteristics that constitute the main body of the mold. High-strength special steel, due to its excellent resistance to deformation, wear resistance, and impact resistance, is the preferred choice for withstanding the repeated pouring, vibrating, and curing environmental stresses of concrete. The uniformity of the material and the pre-treatment process, such as stress relief, are crucial for preventing distortion during long-term use.

Meanwhile, manufacturing accuracy is another pillar of durability. The mold components that undergo precise processing using computer numerical control technology ensure that each mold closure achieves a perfect fit. This level of precision not only directly translates into the excellent geometric dimensions and surface finish of the prefabricated wall panels, but also significantly reduces the wear and defects of the molds and components caused by leakage and misalignment, thereby fundamentally extending the effective service life of the molds.

Design Philosophy: Modularization, Flexibility and Structural Integrity

Excellent mold design is the blueprint for durability. The modular design concept is the core trend of modern prefabricated wall panel molds. Through a standardized and interchangeable component system, the same set of molds can be flexibly configured to produce wall panels of various sizes and specifications. This design not only enhances the utilization rate of the molds and the adaptability of the project, but also ensures that the connection points and the main structure will not fail due to fatigue during repeated assembly and disassembly, thanks to its sturdy locking mechanism and enhanced structural support.

The design also needs to fully consider the dynamic loads during concrete pouring and the vibration force. Reasonable reinforcement layout, uniform force distribution, and user-friendly operation interfaces (such as safe clamping and demolding devices) can all reduce accidental damage to the mold caused by improper operations, thereby ensuring the long-term structural integrity of the mold.

Technical Integration and Future Adaptability

In the digital age, durability also means "technical vitality". When evaluating a prefabricated wall panel mold, its compatibility with the building information model workflow should be considered. A mold system that can seamlessly import BIM design data and support CNC processing can ensure that it can efficiently and accurately respond to constantly changing design requirements throughout its entire lifespan, avoiding premature obsolescence due to technological disconnection.

Furthermore, whether the mold system is convenient for integrating or upgrading sensors and monitoring equipment is also a key point in forward-looking considerations. Intelligent molds can provide real-time feedback on production data, enabling preventive maintenance and allowing for the early detection of potential wear and tear. This is an emerging safeguard for maintaining their long-term high-performance operation.

The supplier's expertise and after-sales support system

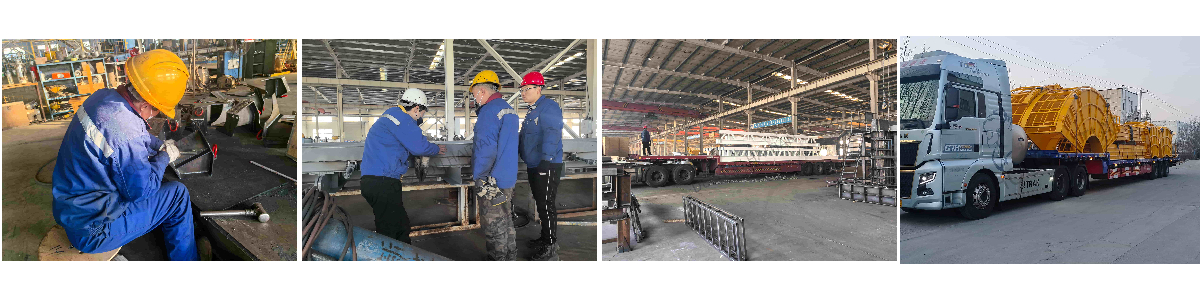

The durability of the mold is not only dependent on the product itself, but also closely related to the partners that create and support it. Choosing a supplier with profound engineering experience and a record of successful projects is crucial. A professional partner can provide full-cycle technical support from design collaboration, force analysis to production optimization, ensuring that the mold operates under the correct parameters from the very first day.

Equally crucial is a strong and responsive after-sales support system. This includes readily available spare parts supply, professional technical maintenance guidance, and rapid problem-solving capabilities. This system forms a secure network that ensures the prefabricated wall panel molds receive the necessary maintenance at any production stage, thereby maximizing their service life.