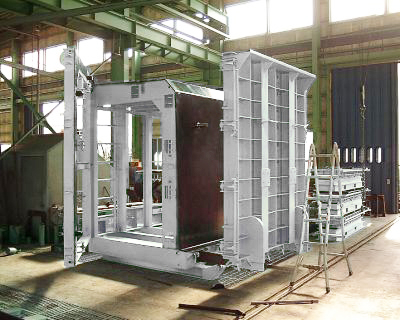

Precast Manhole Mold

1. Customizable to project drawings: Tailors to manhole dimensions, openings, and reinforcement so units fit the site.

2. Inner–outer mold for reliable sealing: Combined inner and outer halves improve watertight performance.

3. Supports embedded parts and sleeves: Holds embeds, ladder brackets, and pipe sleeves in place during casting.

4. Compatible with vibration and curing aids: Works with optional vibration and temperature control for steady consolidation.

5. Durable finish for easier demolding: Precision-treated surfaces reduce sticking and cut post-cast touch-ups.

6. Modular and transport-friendly design: Segmented panels and standard connectors simplify moving and assembly.

The Precast Manhole Mold is designed to turn routine production into a dependable, low-stress process for precast manufacturers. It brings a practical combination of flexibility, sealing performance, and workshop friendliness so that production teams can focus on steady output rather than firefighting small problems. The tool is built to align closely with engineering drawings and site requirements, allowing inlet locations, access features, and reinforcement layouts to be formed in place rather than fitted later. Because the mold is developed with both inner and outer components, it answers the common need for watertight chambers in drainage and sewer systems while keeping demolding and finishing work manageable.Beyond technical capability, the Precast Manhole Mold pays attention to daily use: access points are laid out to make cleaning and inspection straightforward, modular panels simplify transport and setup, and contact surfaces are finished to ease release and minimize post-cast touch up. Optional process aids such as vibration and controlled curing can be used to stabilize concrete consolidation and early strength across varying climates, so manufacturers get more consistent units in less time. Taken together, these features help shops deliver clean, installable manhole units that meet site demands with less rework and fewer surprises. The Precast Manhole Mold is a practical choice for teams that value predictable quality, simple maintenance, and smooth integration into existing production lines.

1.Structural flexibility and drawing alignment

The mold is designed to follow project drawings closely so that manhole geometry matches the intended design without forcing changes in the field. Panels and inserts can be adapted to different diameters and opening arrangements, enabling the tooling to produce a range of chamber styles while preserving tight dimensional control. This adaptability reduces on-site adjustments and helps the finished units fit their intended locations without rework. In practice, that means installers and contractors encounter fewer surprises during installation.

2.Inner and outer layout for watertight performance

A combined inner and outer mold approach is used to strengthen sealing at critical joints and contact faces. That design helps manage hydrostatic pressures and reduces leakage risk after installation. Carefully designed mating surfaces and sealing details ensure that the cast chambers behave as engineered in service conditions, which is especially important for municipal and utility works where water tightness matters for long term performance.

3.Embedded features formed in place

The tooling accepts embedded items directly during casting so ladders, pipe sleeves, benching interfaces, and lifting points are formed in place instead of being cut in later. This approach keeps the finished product neat and saves labor during assembly on site. Built-in guides and fixture locations ensure embeds sit exactly where they should, avoiding alignment headaches and speeding up downstream installation tasks.

4.Compatibility with compaction and curing options

To support consistent concrete quality, the mold is compatible with vibration and controlled curing aids that help consolidation and early strength development. These process supports are available as optional features so producers can tailor the casting routine to local mixes and climate conditions. Better consolidation yields fewer voids and a more uniform surface, which reduces the manual refinement work that often slows production.

5.Smooth demolding and durable surface treatment

Contact faces receive precision finishing and protective treatments intended to minimize adhesion and abrasion. That finishing leads to cleaner demolding behavior and less patching or grinding after release. Because the surfaces are easier to clean and hold up to repeated cycles, the mold keeps producing tidy units for longer before refurbishment is required, protecting both output quality and tooling value.

6.Modular panels for easier logistics and site fit-up

Large molds are broken into manageable panels with standardized connection points to simplify shipping, storage, and assembly. This modular approach reduces transport complexity and makes it easier to install the tooling in yards with constrained space. Quick alignment features and repeatable joints speed up setup so production can return to steady work quicker after relocation or reconfiguration.

7.Workshop friendly design for maintenance and uptime

Routine maintenance is easier thanks to accessible inspection routes, logical component layout, and commonly available spare parts. The mold is arranged so technicians can reach wear areas without full disassembly, and spare part logic follows familiar standards to reduce lead time for replacements. These practical considerations shorten maintenance windows and help shops keep a reliable production cadence.

8.Practical choice for utility and municipal contractors

Overall, this tooling package is tuned to the needs of infrastructure work: it forms watertight chambers that accept embedded fittings, it integrates with process aids that improve concrete quality, and it is built for repeated use while being simple to maintain. For contractors and precast producers who must balance delivery schedules and installation quality, the Precast Manhole Mold offers a pragmatic route to consistent units with fewer surprises during casting, handling, and installation.