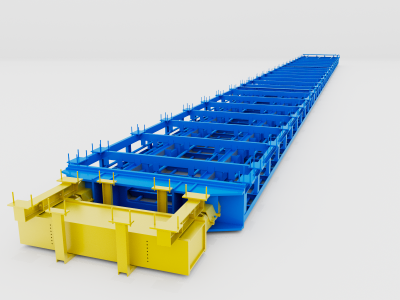

Precast Concrete Curbstone Mold

1. Customizable to Project Drawings:Mold profiles can be tailored to match curb dimensions, edge shapes, and drainage requirements so the final pieces align smoothly with site designs.

2. Supports Various Curb Profiles:The structure accommodates straight, curved, and side-drain curbstone types, helping meet different road, sidewalk, and landscaping applications.

3. Precision Surface Finish:Machined contact faces provide cleaner demolding and sharper edges, reducing surface touch-ups and improving overall curb appearance.

4. Compatible with Compaction Aids:The mold works well with vibration and consolidation tools, helping the concrete settle evenly and enhancing durability.

5. Durable Steel Construction:Reinforced steel plates with protective treatment improve wear resistance and extend mold life through frequent production cycles.

6. Modular and Transport-Friendly Design:Segmented panels and standard connections make the mold easy to move, assemble, and adjust for different precast yard setups.

The Precast Concrete Curbstone Mold is designed to make curb production feel straightforward and dependable on the shop floor. It aims to be the sort of equipment that production teams trust to behave predictably: the mold lines up, reinforcement is placed, concrete is poured, and neat curbstones come out ready for stacking or delivery. That steady performance matters because fewer surprises during casting mean fewer late corrections on site and smoother deliveries to projects.This mold blends practical flexibility with workshop-friendly details. It adapts to project profiles so designers do not have to compromise, and it accepts common process aids that help teams control compaction and curing when mixes or weather conditions change. Contact faces are finished to aid release and to protect the visible edge of each curb, which reduces manual finishing and speeds the flow from casting to shipping. Modular panels and standardized connections make the tooling easier to move and set up, so small yards and larger factories alike can use the same system without heavy rework of their layouts.Beyond the mechanics, the Precast Concrete Curbstone Mold pays attention to daily realities. Lifting points and inspection routes are placed where workers expect them, spare parts follow common standards, and maintenance tasks are kept simple so the mold supports long, steady runs rather than frequent interruptions. For producers who value consistency, low fuss, and clean finishes, this tooling is a practical partner for curb production.

1.Design Flexibility that follows the plan

The tooling respects the original intent of project drawings and profiles. Panels and inserts can be adjusted to produce a range of curb shapes and edge details, which helps the finished units match roadside geometry without on-site trimming. That flexibility lets contractors meet different roadway and landscape needs with the same basic kit, saving time and simplifying inventory of tooling.

2.Surface Quality and Clean Demolding

Contact surfaces are machined and treated to encourage clean release so cast curbstones require minimal touch-up. A tidy release reduces sanding and patching, and produces visible edges that sit well in finished paving. The result is better presentation for architectural projects and less labor in finishing for municipal or highway work.

3.Process Compatibility for Reliable Concrete

The mold is built to work with standard consolidation and curing practices so producers can stabilize their mix performance. Optional compaction aids are accepted without complex retrofitting, helping concrete settle uniformly and reducing the risk of surface blemishes. Curing support helps keep early strength development predictable when ambient conditions vary.

4.Durable Construction to Protect Tooling Value

Steel sections and protective finishes are chosen for long service life under frequent casting cycles. Reinforcements at critical load paths preserve alignment and reduce the chance of distortion. These durable choices mean the mold maintains dimensional accuracy over time and protects the investment in tooling.

5.Logistics and Modularity for Practical Use

A modular layout breaks the mold into manageable panels that ship and assemble with less fuss. Standardized connection points and repeatable joints make setup quicker and reduce the disruption when relocating tooling or changing production layouts. This modularity helps small yards and large plants alike adapt to changing project needs.

6.Workshop Friendly Maintenance and Spare Parts

Daily upkeep is made easier through clear inspection routes and commonly standardized spare parts. Wear items are accessible so routine checks and replacements can be done with minimal downtime. The practical spare parts logic keeps maintenance predictable and simplifies planning across production cycles.

7.Integration Ready for Production Lines

The mold is designed to integrate smoothly with common handling and curing equipment so it fits into existing lines without major reengineering. Lifting points and interface brackets align with standard cranes and transport fixtures, which speeds movement from casting to curing to dispatch.

8.Closing thought

The Precast Concrete Curbstone Mold offers a balanced mix of adaptability, surface quality, and workshop practicality. It is built to reduce the friction of curb production, helping teams deliver consistent, installable units with less rework and more predictable throughput. For manufacturers focused on clean finishes and steady output, this tooling provides a reliable backbone for curb and edge stone production.